|

DISMANTLING THE BOMB:

DISMANTLING THE BOMB: by Alan Sussex

Reprinted from the OUTLOOK, August, 1996

It’s 6:30 p.m. and the small commuter plane drops below the puffy white clouds to land. As the plane makes a low descent and banks sharply to the left, I can see the dirt-covered bunkers below me that contain over 9,000 plutonium "pits." A pit is the heart of a nuclear warhead. I count 60 of the bunkers that hold them.

Aerial view of the U.S.Department of Energy's Pantex Plant.

A flight path for a landing at the Amarillo airport takes you directly over the storage bunkers and much of the 16,000 acres (25 square miles) that is encompassed by the Pantex plant. This the where the nation’s tens of thousands of nuclear warheads for artillery shells, missiles and bombs have been assembled and disassembled since the late 1940’s. With the end of the cold war and SALT (Strategic Arms Limitation Treaty) agreement, only disassembly is being done here. Over 50,000 warheads have been taken apart here to date, some for testing, some to be rebuilt into new weapons, but now over 9,000 remain dismantled.

Many of the more than 6,000 parts contained in a B-61 nuclear bomb are spread before a partially disassembled weapon (center) and a fully assembled weapon in the background.

There are over 6,000 parts in a B-41 nuclear bomb including the pit, the heart of

a warhead which makes the nuclear explosion possible. The pits range from the size of

a baseball to that of a bowling ball, depending on the intended explosion which can be

from kilo tons to mega tons

(the explosive equivalent of thousands or millions of tons of TNT, respectively).

A pit is composed of an outer shell of beryllium or stainless steel ¼ inch thick and an inner shell of plutonium metal about ¼ inch thick. One cubic inch of plutonium weighs 11.4 ounces. By comparison, a cubic inch of gold weighs 11.2 ounces, and a cubic inch of lead weighs 6.6 ounces. In a warhead, the plutonium Pit is enclosed with detonators that when triggered create a uniform wave of explosions from all directions at once, imploding the plutonium core. Without the exterior high explosives, a nuclear explosion cannot take place, but deadly accidents can occur anyway. It is possible to breach the outer shell, allowing the deadly radioactive material to escape into the atmosphere. Plutonium has a half life of 22,500 years, so a radioactive spill can be deadly for well over 100,000 years. Plutonium is one of the most deadly carcinogens (cancer causing agents) known.

The following morning at 6:00a.m., it’s still dark as I drive east on Highway 60. Pantex is lit up like a small city in the distance. It is workplace for about 3,600 employees, many of whom live in Amarillo, 20 minutes to the west. Pantex is the area’s largest employer next to the school district. A nearly full moon lights up the rows of bunkers to my left. I think about those bunkers in the flight path, and what kind of scenario it might take to penetrate one and cause a fire. Studies have been conducted to slightly alter the approach angle of planes landing at the Amarillo airport, but the flight path cannot be readily changed much because the runway is in a direct line with Pantex.

Turning left at Road 2373, I head towards Building 16-12 where I’ll check in. I’m early, it’s 6:15a.m. At Building 16-12, a large blue sign out front reads "US Department of Energy/PANTEX/Pursuit of Excellence through Involvement." The lobby seems almost empty. While I am waiting, four workers wheel a heavy rack past me cradling two small nuclear bombs, each about six feet long and twelve inches in diameter. Neither bomb contains its high explosives or plutonium Pit any longer, I’m told later. After a short wait, paramilitary escorts arrive wearing camouflage uniforms, side arms and communications gear. Two women and six men process me in. They are efficient and friendly. For the next nine hours they will watch every move I make and keep me and their other guests inside tight protective perimeters. My picture ID is checked against the list. I’m given a Pantex badge, a name tag and a dosimeter which will register any radiation exposure. Lastly, they check me with a wand metal detector, like at the airports.

When nuclear bombs such as these B57s are transported by truck at Pantex, they are secured inside the vehicles following federally-approved safty standards.

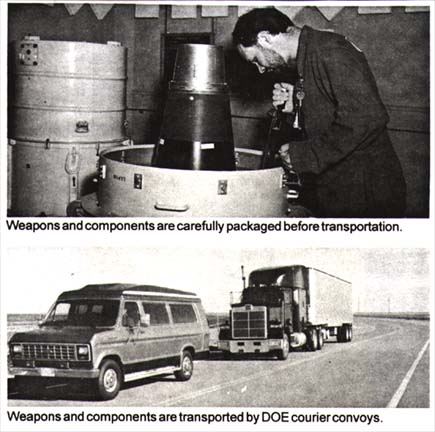

Nuclear warheads arrive at Pantex in armored tractor trailer trucks, unmarked and escorted by paramilitary guards, which stay in constant communication and are tracked by satellite.

Special armored trains were formerly used, and they can be seen as we drive over to Zone 4, Magazine 20, where the Pits are stored. The fence line between us and the bunkers is 12 to 15 feet high. Four and five rows of coiled razor wire run horizontally along the fence, with another four rows lying on the ground inside of it. Further inside are dish-shaped motion detectors, buried sensing devices and armed guards in 30 foot towers. There is a second fence line 100 yards inside the outer fence. In between is "no man’s land." The second fence line is as elaborate and deadly as the first. Coils of razor wire are wrapped around the tall security lights.

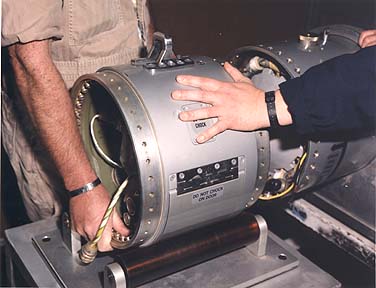

Armed guards wave us past two sets of gates and a row of armored cars into the bunker storage area. Twenty-two of the bunkers are used for Pit storage. The rest are used for temporary stashing of nuclear weapons coming and going from Pantex. Each "igloo" (as the bunkers are called) has twenty-five tons of special blast resistant concrete blocks in front of the doors. It requires a very large fork lift to move them. These blocks are meant to delay any intruders. There are steel blast doors behind the blocks. These are now opened. Portable tracks are moved in place so that remote controlled vehicle can load or unload each thirty-gallon container (each containing one Pit) into its programmed location on a rack inside the igloo. An operator controls the transfer from a mobile trailer fifty feet away. There are various security sensors inside and outside the bunkers and on the roof.

We step inside the bunker. It is like a quonset hut but with an arched roof fifteen feet high and fifty feet deep. The corrugated steel walls are 3/8 of an inch thick. The outside of the wall is covered with four to six feet of earth. Two dozen drums sit in a steel rack while the operator goes through the loading process. Each drum has its own footprint or signature and is computer cataloged with a spectrograph. When we go back outside, an armored car has pulled up to the location. A helmeted guard with an M-60 machine gun is stationed on the roof.

Our next stop is Security Building 12-75. Laid out on a table are different weapons that the security forces use. A 357 magnum and a 45 caliber pistol, a submachine gun, an M15 rifle, and HK-30 rifle with a long-range scope, and a 60 caliber machine gun that fires up to 650 rounds per minute. There are night vision scopes and goggles, kevlar body armor and ridged body shields. There is an armored car nearby with a roof opening for a mounted machine gun. The "special force" of 500 at Pantex is the largest group of paramilitaries in Texas.

We next come to Building 11-51, cancer research. It’s over 90 degrees now. I face into the constant breeze to cool off. Some of the research is being conducted with an x-ray photo electron spectrometer previously used to analyze material samples for traces of high explosives. The Department of Energy (or DOE, pronounced DEE OH EE, as it is called almost everywhere) has given Pantex and Texas University a million dollar grant for this research.

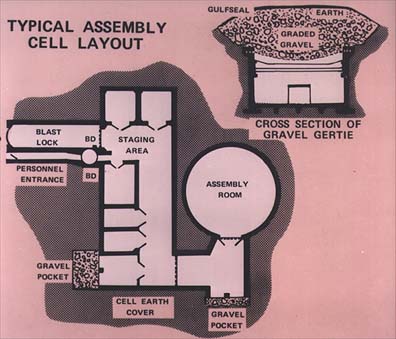

Although the sun is out, there’s a light thundershower as we break for lunch. After lunch, it’s over to Building 12-10 where the assembly/disassembly cells (called "Gravel Gerties") are. There are thirteen Gravel Gerties. Each is arched about 40 feet high. The top seventeen feet are composed of compacted gravel, which accounts for the nickname, and over the gravel is a thick gunnite cap for rain protection. On the inside, the ceiling is 21.5 feet high. The interior surface is four-foot-thick, reinforced, blast resistant concrete. On top of that are three woven mesh layers of steel cables, some two inches in diameter, then the 17 feet of gravel. If a blast occurs, the roof is meant to lift up, absorbing the energy, and then settle back down, trapping the radioactive material inside. Corridors through which the weapons are brought into and out of the structure are also designed to channel and absorb any accidental blast. The walls of the corridors are formed with four feet of special blast concrete and 15 feet of soil on each side. Guarding each entrance are two sets of heavy steel doors weighing one ton each, with an air lock in between them. The inner door is much like a bank vault door with a round revolving crank used to move large horizontal locking pins into a steel door frame. The weapons are brought in and opened one at a time in the Gravel Gerties.

Replicas of the Gravel Gerties have been blast tested at a Nevada test site to make sure they work as designed. Inside the Gravel Gerties are working bays or cells where the warheads are x-rayed and disassembled. The walls of these cells have double protective layers on each side: four feet of concrete and 13.5 feet of gravel, then another four feet of concrete and another 3.5 feet o gravel. An additional two sets of blast doors allow entry into each cell. Opposite those doors are vertical, one-foot-thick I-beams designed to catch the doors if they are blown off, directing the blast down the corridors towards yet other blast doors.

Artist's rendering of assembly/disaddembly cell or "Gravel Gerite" at U.S. Department of Energy's Pantes Plant. These structures are designed to contain or mitigate the effects of an accidental high explosive detonation during assembly/disassembly operations. While no accident of this tyoe has ever occured at Pantex, full-scale testing of these structures in Nevada have proven their worth.

In order to enter the x-ray cell you must first place your hand on a glass-surfaced scanner. The former retina scan is no longer used, for reasons that were not explained. Signing in is required, in case of an accident. The second door going into this cell turns on its axis like a revolving door, only this revolving door weighs 2,000 pounds. The wedge-shape space inside is small as I push open door 180a and enter the room behind it. The door will lock in place if an explosion occurs. Because there are so many different versions of bombs, artillery shells and missile warheads, each one must be x-rayed to get a precise look at how it was put together so that it can be taken apart more safely.

In the x-ray cell, there is a remote controlled linear accelerator, or x-ray head, capable of turning in any direction, which hangs from an overhead gantry. This x-ray head weighs 1700 pounds and is 29 inches long by 32 inches wide and 48 inches deep: a giant version of the one in your dentist’s office. This one is powered by 900 million volts, can penetrate 15 inches of steel, and is lethal with a ten second exposure. Its laser site can pinpoint any part of the warhead lying on turntable below. Bombs as large as five feet in diameter and ten feet long have been x-rayed here. Film is attached to a screen behind the table. Technicians watch while a color-enhanced image is made to identify any potential problem areas or structural flaws. A new CATSCAN x-ray machine will be operational around September 1996 and will deliver more accurate 360 degree slices for viewing. The operators of these giant and deadly x-ray machines are situated in a remote control room located a safe distance from where the warheads are actually x-rayed.

After determining the type of construction and making prints to work with, Pantex technicians prepare a detailed work sheet for dismantling each nuclear warhead and then transfer the warhead to a disassembly cell. Another is required to enter any of the disassembly cells. As I pass through a double set of blast doors, my first thought is that it looks like an operating room: bright lights, operating table, spotlessly clean. Near the top of the ceiling I can see an ultra-violet sensor that can detect the slightest spark or flame. It automatically alerts emergency personnel and triggers a "deluge system," pumping thousands of gallons of water into the cell in seconds from high pressure outlets in the ceiling. The system has on occasion been triggered accidentally, flooding cells and corridors. There are also heat and air sensors in the cells.

The parachute is removed from the tail section during the disassembly process.

To minimize static buildup, workers wear ground straps while taking apart a warhead, as do their "readers," who describe to them each move form the worksheet. Warheads are also grounded. The floor is composed of special static reducing composite material and feels like soft tile when walked on. It takes anywhere from one day to three weeks to take apart a bomb, depending upon its construction. Workers wear lead aprons, gloves and shielded face masks to protect themselves from radioactive emissions from the Pit. They cut through the bonded outer layer of high explosives and detonators using a water jet saw. The amount of radiation that workers receive depends on how long and how close they are to the Pits. Workers are allowed to receive up to one rem of radiation a year. The average person not working around this material, such as you or I, receives about a quarter to a third of that amount in a year.

One of the components removed during the disassembly of nuclear weapons is the pre-flight control panel.

After the fast burning high explosives are removed, they are taken to another onsite

location and burned. Because of the continuous release of energy within the plutonium

core, the now exposed stainless steel Pit is perpetually warm. When disassembly is

completed, all of the pieces are recycled. Uranium parts are returned to a plant in Oak

Ridge, Tennessee.

There is a predetermined outlet for all component parts resulting from a nuclear weapon. Uranium parts are returned to the Oak Ridge Y-12 plant, tritium bearing parts are returned to Savannah River, and recyclable parts are returned to the original site of manufacture. Other waste materials are separated for recycling or shipment to EPA approved disposal sites. Non-nuclear high explosive wastes are burned on site and the resulting ashes are shipped to an EPA approved disposal site. These particular bins containing copper, aluminum, silver, gold, and platinum are all nonnuclear parts that are recycled in the Amarillo area.

Tritium bearing parts are returned to the Savannah River Plant in South

Carolina. Recyclable parts are returned to the original manufacturers. All other parts are

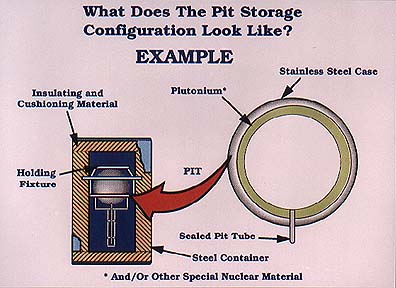

put through a process that makes them unrecognizable and are recycled locally. The Pit is

then clamped and bolted with a set of jaws into a holding fixture. It is the only part of

the dismantled bomb which will remain at the Pantex facility. The Pit still locked in its

holding device is placed into a larger ¼ inch thick egg-shaped stainless steel housing

filled with inert argon gas to prevent corrosion and welded tight. After being tested for

leaks, it is placed into a cushioned and insulated ¼ inch thick stainless steel, 30

gallon "AT-400 Drum" and its lid is screwed on. The AT-400 container was

recently developed for transportation and storage of the Pits. This new drum allows for

safer handling and has an estimated life of 50 years. Each AT-400 Drum costs $5,000. It

costs between $10,000 to $25,000 to assemble each warhead.

Following removal from a nuclear weapon, the component containing plutonium, commonly referred to as the "pit", is currently stored at Pantex Plant on an interim basis. This hermetically sealed unit is placed in a fixture inside a high carbon shipping container. These containers are then placed in the highly secure storage bunkers at Pantex Plant.

Pantex has a budget of $120 million a year. About half that amount is spent dismantling nuclear warheads. Most of the rest is spent on research and development.

Pantex officials readily admit that mistakes and accidents have occurred in the past. They emphasize that they are trying to correct any present problems and/or errors. Perhaps the biggest continuing problem is radioactive contamination.

Test firing of high explosives from 1952 to 1984 was done at Firing Site 5 in the Pantex complex, using depleted uranium and beryllium to simulate plutonium. These tests contaminated the soil to a depth of nine inches with radioactive material.

Burning of high explosives has contaminated the soil in some locations to as much as 20 feet deep. Thirty-seven cleanup sites exist on fifty-eight acres. Already it is estimated that 500 drums of soil contaminated with depleted uranium will need to be moved to other storage locations. Some contamination from explosives (not radioactive) has already reached the Perched Aquifer, which lies 200 to 300 feet below the surface under Pantex. A waste water treatment plant now draws up water from the Perched, filters it through activated carbon and then returns it to the aquifer. The Perched is only a relatively small local aquifer. The much larger Oglalla aquifer lies 100 feet below the Perched and underlies seven other midwestern prairie states. The Oglalla Aquifer is a source for much agricultural water in America’s heartland Grain Belt. So far, the Oglalla Aquifer does not show any contamination from Pantex. No radioactive materials have yet been found in the waters of either aquifer. Fifteen wells neighboring the Pantex facility continue to be tested and monitored regularly.

An accident occurred in 1989 in which tritium, a radioactive gas used in combination with plutonium to provide the explosive energy in a hydrogen bomb, was released when a valve failed while a weapon was being dismantled. Cell I in Building 12-44 remains closed today. Five workers were exposed to high but non-lethal doses of radiation. No other major accidents have been reported so far.

|

Pantex currently has over 9,000 Pits stored on site. It is permitted to store up to 12,000 Pits. A $30 million environmental impact report (EIR) is in its final stages; if approved it would allow up to 20,000 Pits to be stored. With the growing number of Pits, and many more to come, some scientists have suggested that they could be fired into the sun with rockets. Aside from the cost, the chief drawback to this idea is that if such a rocket were to explode in our atmosphere, as has sometimes happened with our past NASA rocket launchings, it would be catastrophic. Other scientists have proposed that we could bore deep holes past ground water and just drop the radioactive waste in. This plan would have obvious adverse results in areas of geological instability, and so far, no proposed site has appeared to be clearly safe. Some European nuclear reactors use a combination of recycled plutonium and uranium to generate electricity. This practice has the appeal of utility, but at best it increases the amount of low level waste. At worst it might result in Chernobyl-type disasters. Meanwhile, the DOE is in no hurry to destroy the Pits, since it may some day come to pass that new bombs are desired.

The DOE says that in its 50 mixed-waste sites it currently has 589,482 cubic meters of mixed waste in storage and will generate another 1,370,000 cubic meters of mixed waste and an additional 144,000 cubic meters of low level radioactive waste, called "RA waste" over the next 20 years. Mixed waste is the term used for a combination of low level RA waste and other hazardous waste. This does not include any present or future high-level RA (that is, extremely radioactive) waste, nor any present or future commercial reactor waste, or any potential RA waste from hospitals, universities and research facilities. The estimated cost of cleaning up the radioactive waste generated in plutonium production alone is estimated to be about $300 billion, a little more than $1,000 for every man, woman and child in America.

As I drive away from the sprawling Pantex facility, back down US Highway 60 towards Amarillo, a B-1 Stealth Bomber is just taking off from a military base next to the highway. It is quite possibly the last model of a manned nuclear bomber that will ever be made. Looking back to the road, I pass an old abandoned gas station from the 1950’s. On its roof is a large simulated nuclear bomb, now deteriorating, once used to attract business from Pantex workers. Those days are over. Pantex remains.

I have personally visited and inspected various nuclear facilities, RA waste site and proposed RA waste sites such as the Hanford Nuclear Reservation in Richland, WA, the US Ecology RA waste site in Nevada, the Kerr-McGee Tritium production facility in Gore, OK, the Nevada Test site in Alamogordo, NM, the Waste Isolation Pilot Project, Carlsbad, NM, and the Ward Valley site in Mojave, CA, among others. Pantex may be one of the cleaner facilities that handle RA waste materials. Because of closures at Hanford and Rocky Flats, and problems at other facilities, Pantex may be asked to increase its storage capacity of RA waste materials.

Current RA storage locations are used because they are the only places available now, not because they are safe. In America as elsewhere, nuclear production and storage centers are vulnerable to earthquakes, tornadoes, floods and other natural disasters. Proposed locations appear to be picked primarily because they are convenient to transportation systems and centrally located among "generators," and where local residents are least likely to object strenuously or create a political backlash. There may never be a truly "safe" or "good" place on earth for such operations as long as water runs and the wind blows.

This may be the legacy of our generation: to have to keep moving this rapidly accumulating and invisibly toxic stuff from one place to another, and in each new location contaminating more soil, air and water, always creating ever more waste to be moved or somehow dealt with. Meanwhile, each day, each nuclear power plant produces more RA waste, adding to the still unsolved problem.

xxx